How to Compare Plate Boats

When you buy a boat, you are buying its performance, quality and safety. Sometimes it’s hard to tell what is real and what is nothing more than a gimmick. We break down the common myths about Aluminum Plate Fishing Boats.

The following information is designed to provide answers to common queries, allowing you to compare plate boats in an informed manner.

Get In Touch

THREE TYPES OF ALUMINIUM BOATS

There are three main types of aluminium boats on the market. Below, we break down each type and compare aluminium boats commonly sold across Australia.

Plate Boats: Custom built from 5083 structural marine grade aluminium, designed and built as a traditional fully framed vessel. These vessels typically are used in commercial applications and meet the strict requirements of the NSCV. Designed to AS4132.2. These boats typically use closed cell foam for floatation. The Seatamer PTF series are true aluminium plate boats.

Production Boats: Mass produced boats for recreational purposes. Typically, these vessels are made with plate aluminium for the planning sheet and side sheets used in conjunction with extruded profiles for the keel and chine joints. Typically they are not fully framed or welded. Often they use Sikaflex to glue the side stiffeners to the side sheet to stop plate deformity. The structural design and warranty is for recreational use only. Typically designed to AS1799.1 Some designs use air pockets and not foam for flotation.

Press Boats: Mass produced for the once a month boater, these are affordable family boats made with low grade aluminium. As a result, the stepped hull and side sheets can be pressed by a simple punch. Common examples include a tinny or runabout.

PROVEN DESIGN – AUSTRALIAN STANDARS

Australian design standards apply to ALL boats regardless of who builds them.

- AS4132.2 -1993 Design & Construction – for Pro Boats and commercial applications.

- AS1799.1 – 2009 Small Power craft – for recreational boats.

- AS3004.2 – 2009 Electrical Installations for vessels.

When vessels claim to meet a design standard, there are still vital considerations that you must be aware of. These include;

- Is the vessel fully framed?

- Has level buoyancy been achieved with foam or air?

- Are the fuel tanks separate from the hull?

- Which joints are fully welded on both sides? And finally;

- Why would I want a fishing boat that is based on a commercial design?

Ask a Question about design standards

WHAT IS THE DIFFERENCE IN CONSTRUCTION?

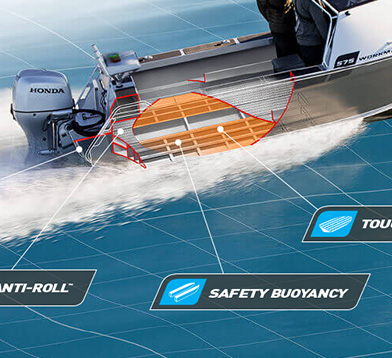

Aluminium plate boats can be separated into two main groups; those that are fully framed and those that are not.

The key question here is this, what is a fully framed boat and what difference does it really make?

A frame can either be solid or have the centre cut out to reduce weight. It can also be one piece or welded.

An effective frame should connect the planning sheets to the side sheets, to the floor and to the keel. This is where the vessels strength comes from.

The planning sheet is supported by stringers that should be one single piece that run the length of the boat spaced at 250mm centres.

Vessels gain their strength from frames and stringers. Pro Tournament boats are fully framed using a pressed G frame top for additional strength and marine grade T section to support the floor.

-

Seatamer - fully framed

Seatamer - fully framed -

Yellowfin - extrusion only

Yellowfin - extrusion only

Compare the difference between pressed aluminium boats, production aluminium boats and commercial plate boats. Compare the boats!

yourself

For over 25 years, Seatamer has been building custom, aluminium plate fishing boats in Australia.

| Seatamer | Surtees | Stabicraft | Yellowfin | Formosa | |

|---|---|---|---|---|---|

| Australian Made | |||||

| Australian Owned | |||||

| Fully Framed | |||||

| Foam Flotation | |||||

| 100% Customisation | |||||

| Proven Commercial Hull | |||||

| Seperate Fuel Tank | |||||

| Sold by Manufacturer | |||||

| Warranty | 3 years Commercial | 10 years Recreational | 3 years Recreational | 1 years Recreational | 3 years Recreational |

Foam flotation or air chamber floatation?

Boats should have a flotation capability to ensure that when something goes wrong, your vessel will remain afloat. Even if it is upside down, this functionality will allow you to hang on to it. Makes sense right?

Vessels with foam flotation allow you to shoot it, run it aground, drill holes in it or even leave the bungs out. No matter what, it still won’t sink.

Vessels with air floatation won’t sink unless you do any of the things above.

The Australian Design standard AS1799.1:2009 says “Wherever practicable, integral void air compartments should be avoided as a means of providing buoyancy”.

This is only important if something goes wrong. When it does it’s all too late.

-

No matter how many holes in

No matter how many holes in

this hull it will not sink -

One pinhole means flotation is compromisedhttps://www.surteesboats.com

One pinhole means flotation is compromisedhttps://www.surteesboats.com

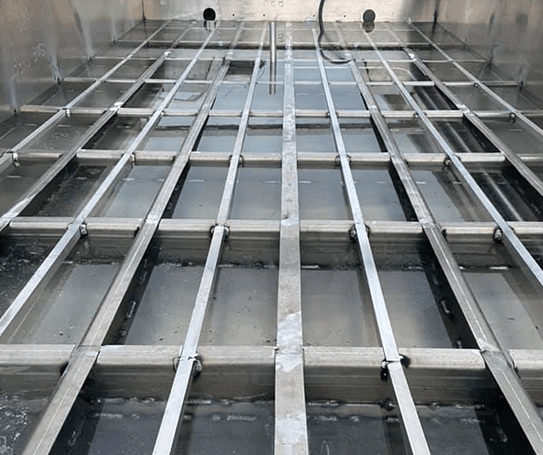

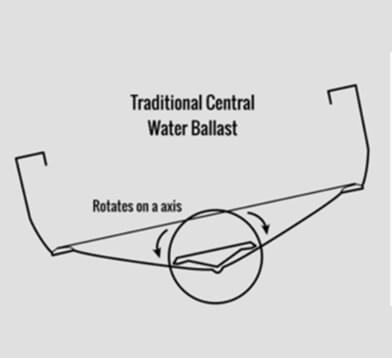

FLOODING BALLAST

The use of a ballast in a boat is not new. In fact, it has been done for centuries. Most large boats have ballast tanks that allow vessels to control where they sit in the water. Cargo ships, for example, utilise ballast to help balance themselves.

A flooding ballast on a small vessel is a solution to mask design compromises.

Vessels that are too light for their size, too narrow for their length, or too steep in their deadrise may incorporate a flooding ballast to overcome these trade-offs in design. There is no doubt any boats stability will improve at rest if they have ballast.

However, if the vessel needs ballast or ballast would improve the vessels performance. Please don’t remove the boats frames that attach to the keel and give the vessel its strength. Make the ballast tank removable so the inside of the hull is not exposed to salt water and it can be replaced.

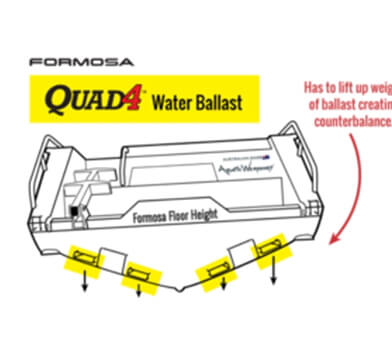

FORMASA Q&A

The following question was found on the Formosa website.

“Questions to ask: If other manufacturers offer a water trap to keep water in the ballast tank for certain sea conditions, then ask why you need this feature to get home? We’d like to know because our boats get home every time. We don’t see a need for this feature other than for marketing reasons.”

This reinforces the point that in small boats, ballast is essentially used to overcome design compromises. During the rest or underway phase, boats under 12 metres shouldn’t need ballast if they have a balanced design. Ballast in plate alloy fishing boats, therefore, is a marketing gimmick.

-

FORMOSA

FORMOSARHS extrusion is welded to the planning sheet creating an water retention point inside the hull.

-

FORMOSA SAYS…

FORMOSA SAYS…Its all a marketing gimmick One chamber or four it has the same effect. The real difference based on volume.

-

100% customisation

Here is another key aspect to consider as you compare plate boats. What is the difference between options and customisation? Options allow you to add features to existing predetermined locations, while customisation enables you add or remove any features you do or don’t want.

When you spend $100K or more on a boat, you should be able to receive exactly what you want. Only boats that are custom built with transparency can achieve this result.

-

Layout – Extra fuel etc

Framed and foamed boats can be customised by size, shape and layout below the deck. The ability to personalise customise your vessel also applies to the addition of extra fuel, freshwater and storage.

Through the PTF Seatamer series, you can have your console just how you want it. Customisation during construction means the boat is built for you, meaning you receive everything you want and nothing you don’t. Through this layout plan, everything is exactly where you want it.

-

WHERE ARE THEY MADE?

Seatamer: Toronto, NSW

Surtees: New Zealand

Stabicraft: New Zealand

Yellowfin: Queensland

Formosa: Queensland

-

WHERE DOES THE MONEY GO?

Seatamer: Family owned, Australia

Surtees: Family owned, New Zealand

Stabicraft: Family owned, New Zealand

Yellowfin: Corporate, United States of America

Formosa: Family owned, Australia

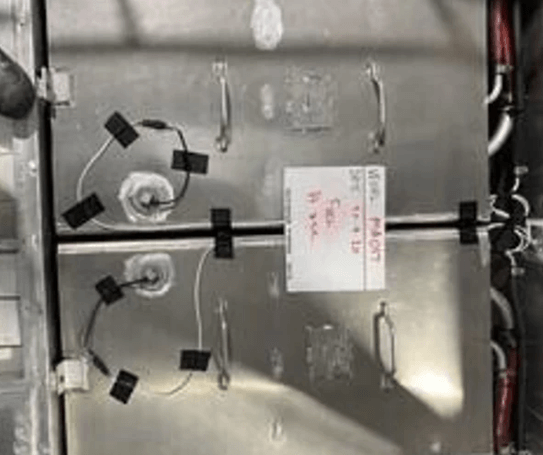

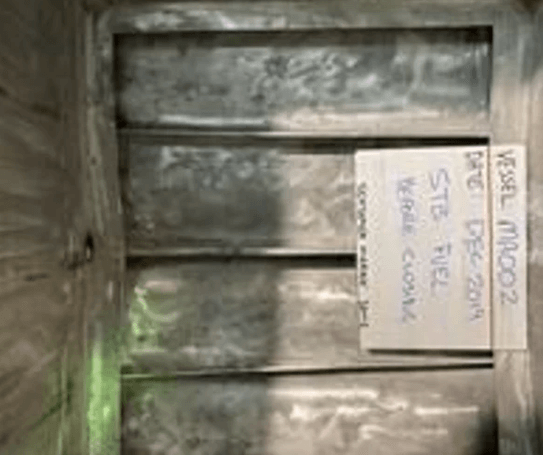

FUEL TANKS

Fuel tanks are often the most crucial and problematic parts of any boat. When functioning well, all is good. When they break down, however, you will be left stranded.

Independent Fuel tanks are removable for cleaning, repair or replacement. On the other hand, upgradeable commercial integrated fuel tanks can be welded into the vessel’s structure. However, they cannot be removed, replaced or upgraded for commercial use.

Pictured RIGHT are 2 x 200L fuel tanks in a 7.4M Mono running twin 200HP Mercury. The fuel tanks are in a cofferdam, accessible through a floor plate on the back deck. They can be cleaned and serviced over the next 15 – 20 years. Pulling the fuel tanks out and cleaning them as you replace engines is the best recommended practice.

DEFINITIONS & PURPOSE

There are industry specific terms to describe vessels and the vessel performance. Here are a few key explanations.

CHINE

The chine is the small hull section on the outer edge of the hull, joining the side sheet and the planning sheet. Each chine has two main functions. At the aft, its size and angle determine how hard and sharp the vessel can turn. The more aggressive the angle, the harder the vessel will turn. Too much of an angle can cause other issues.

A single digit negative angel (-2 degrees) works best for the chine. Located at the front, the chine keeps the vessel’s noise level low when the bow plunges into the water and glides over each wave. If the chine is too small, the bow goes too deep, too big and thud, thud, thud.

The best chines taper in size from aft to bow, possess a single digit negative angle and hold the bow out of the water without dunking or slapping.

DEADRISE

The angle of the v hull typically measured at the transom. The size of the deadrise determines how the hull will perform while planning and moving though chop swell and at rest. The problem with measuring the deadrise at the transom is that most modern vessels have a transitioning deadrise that changes every 300mm as you move aft forward to the bow.

The bigger the deadrise, the less stable it will be at rest. A large deadrise will perform well in a messy sea, but perform poorly on the plan in flat conditions.

Vessels with a large deadrise can often have a ballast to offset the lower stability at rest.

16 – 17 degrees is balanced deadrise for most plate mono hulls. Just one degree higher or lower can make a big difference.

WARRANTY

A warranty is only as good as its exclusions. As you compare plate boats, it is essential to consider this question; what is covered in most Aluminium boat warranties? The aluminium sheet or extrusion will not fail. The weld will not crack under “normal use”.

What’s not covered – electrolysis, any commercial use and in some cases any overuse. It’s all in the fine print.

What’s the difference between commercial and recreational warranties? Commercial warranties have no limits on use. You can use the vessel every day for the first 1095 days, for fishing, or any commercial application, and it’s covered. It will also be time for the 3rd engine.

Electrolysis – caused by saltwater and electrical currents, it breaks down the aluminium. The most common place for electrolysis is along the centre line. Flooding ballasts allow salt water to the inside of the hull. They must be meticulously maintained to prevent degradation of the hull.

Seatamer commercial hull Verified by an independent ASMA report, this Seatamer commercial hull has been in the water and operational for the last 6205 days (17 years) and remains as structurally sound as the day it was delivered.

DISCLAIMER

The information provided is accurate to the best of the information provided by each of the manufactures via their websites. If any information is inaccurate we will correct it. The purpose of this information is to provide an accurate comparison of the vessels and their construction.